....Create environmentally safe keratin-based fuel cell membranes for a green economy.

www.anthropocenemagazine.org

www.anthropocenemagazine.org

40 million tons of chicken feathers are incinerated each year. Why not make renewable energy from them?

Repurposing waste chicken feathers to make renewable energy

Researchers used chicken feather waste to make membranes for hydrogen fuel cells. The inventive membranes are non-toxic and cost less than traditional ones.

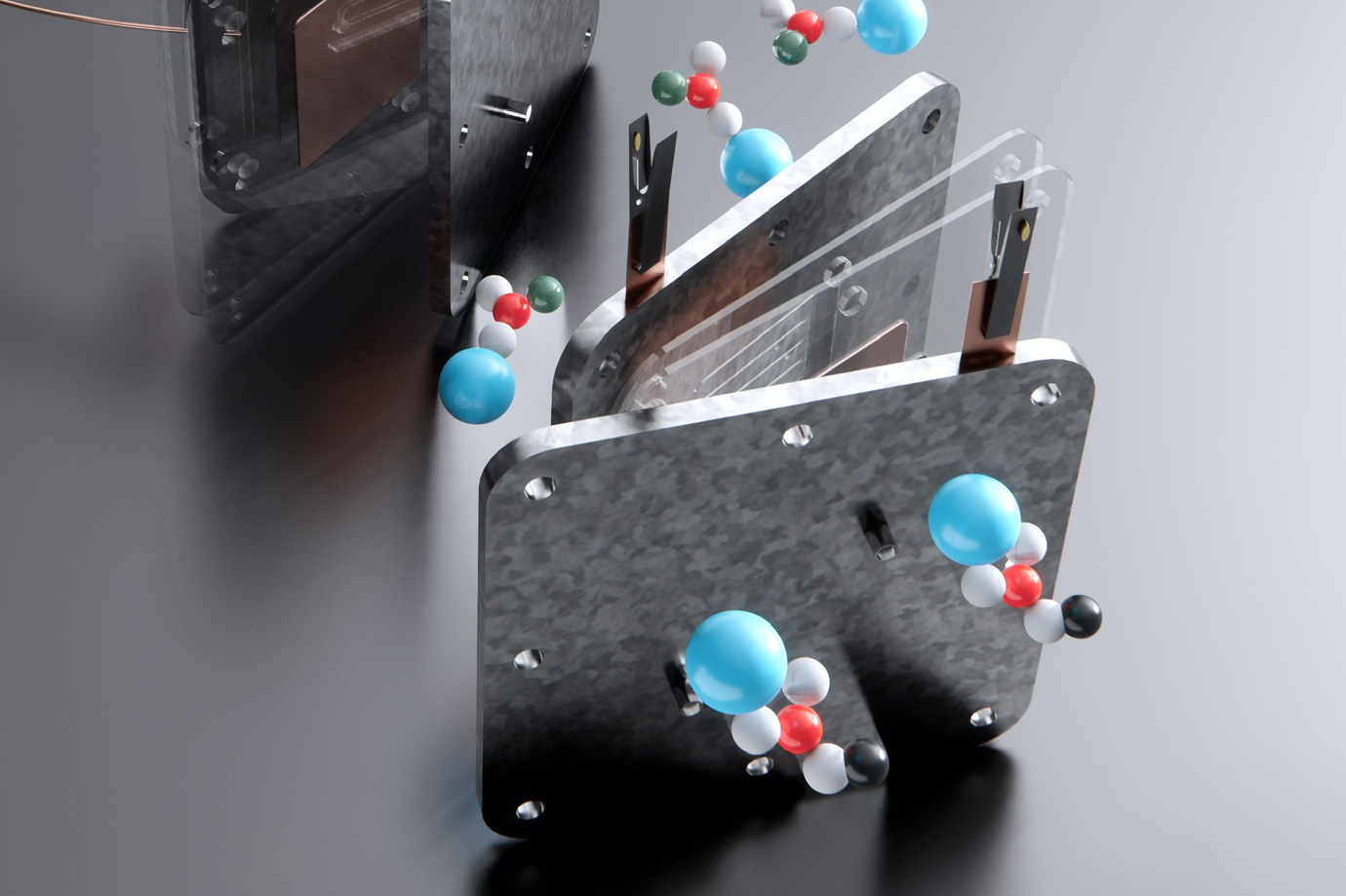

However, permeable keratin brings the possibility of a non-toxic alternative. First, Mezzenga and team set about isolating the keratin from chicken feathers using an environmentally-friendly process, then applying a heat treatment to transform the ingredient into fibrils.

Crucially, these threadlike strands of protein molecules are incredibly resilient under conditions like the high temperatures of a fuel cell, and so made robust building blocks. The fibrils were then mixed with other ingredients to enhance their electrical conductivity, then dried and fashioned into a flat membrane. Finally, this was incorporated into the design of a commercial hydrogen fuel cell.

When the researchers tested it out, it was a feather-fuelled success: the fuel cell was able to convert hydrogen and oxygen into electricity, with proof in the fact that it powered two LED lamps. In further testing, it drove a motor-powered fan and a toy car. Aside from electricity, the fuel cell’s only byproduct was water.

Mezzenga says he’s excited about “the clear demonstration that food waste, currently ending up in incineration or in the very best scenario—some sort of animal feed, can be converted into membranes for the generation of clean electric energy.”

The energy the feather membrane created was not only comparable to that of traditional fuel cells, but cost less than half as much to produce, and without the usual environmental impact, the researchers found. “We start from side streams which are typically burned (generating CO2), and instead of contributing to CO2 emissions, we use them for production of energy at zero carbon footprint,” Mezzenga explains. “The overall carbon balance is therefore obviously negative.”

This no-emissions alternative to incineration could help to scale back agriculture’s considerable emissions impact, while powering the transition to clean energy—quite an impressive pair of accomplishments for the humble and unloved chicken feather.

Mezzenga and team are now enthusiastically focused on bringing their inventive membrane tech into the mainstream. “We plan to convert this laboratory proof-of-concept into a profitable technology, capable of yielding clean energy while preserving the environment,” he says. “We are convinced this can be done at an industrial scale.”